1 SIMPLE DIES:

Simple dies or single action dies perform single

operation for each stroke of the press slide. The operation

may be any one of the operations listed under cutting or

forming dies.

2.COMPOUND DIES:

In compound dies,two or more cutting operations

may be performed at one station by one stroke of the press.

Compound dies are more accurate and economical in mass

production as compared to single operartion dies.

For example, a washer component is made by one

stroke of the press in compound die. The washer is produced

by simultaneous blanking and Piercing operations.

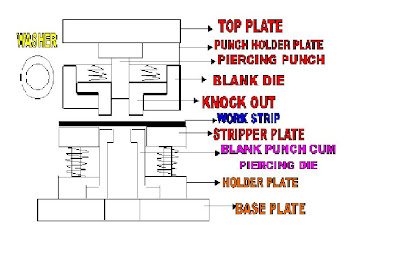

Die construction:

Here the blank punch cum piercing die is

mounted on the bottom of the bottom plate which

is bolsted with machine bed. Blank die and piercing

punch are mounted on the top plate which is mounted

on the press ram. A knockout is placed between

blankdie and piercing punch which is used for to

eject the component from the die. A stripper plate is

held with blank punch which is to strip out strip from

the punch after the operation completed.

3.COMBINATION DIES:

In combination dies more than one operations may be

performed at one station. It is differs from compound dies.

In combination dies cutting and non- cutting operations done

at one station by one stroke of the press.

1.BACKUP PLATE 2.PUNCH HOLDER PLATE

3.BLANK PUNCH CUM DRAW DIE 4.KNOCKOUT

5.STRIPPER PLATE 6.DIE PLATE 7.PRESSURE PAD

8.FORMING PUNCH 9.BASE PLATE.

A cup shaped component is produced in combination dies.

Blank punch cum draw die is mounted on the punch holder and

it is fastened to the press ram.Knockout is held inside the blank

punch which is push out the part from the draw die. A stripper

plate is also held with blank punch.

Blank die and inner size form punch are mounted on the

base plate which are held on the press bed. Pressure pad is

placed between blank die and form punch, which is used for

giving uniform drawing and also to eject the cup from the

form punch.

The sheet metal is placed between the blank punch

and die. During operation, the blank punch first cut

the outer of the blank in sheet metal and also

to form as a cup. Pressure pad helps the uniform and

rigid formation of cup. A diecushion is permanently

mounted under the press machine bed, which helps

uniform drawing and also to eject the part after return

stroke of ram.

4.PROGRESSIVE OR FOLLOW DIE:

Progressive die has a series of stations. At each station

, an operation is performed on a workpiece during a stroke of

the press.Between stroke, the piece in the metal strip is

transferred to the next station.A finished work is made at

each stroke of the press.

For example, in progressive die a rectangle blank part

have two round holes at corners and a one square hole at

the center.

Here the component is completed for three station.

At first station,two coner holes to be pierced on the sheet metal.

At second station,first the pilots are correctly guide the already

pierced holes and then center square hole is done one the

sheet metal.At that same time,two corner holes are pierced out

at first station for next component(second part).

Then the strip is moved at station-3. In this stage,

the component is blanked out from the sheet metal. At the

same time,in first stagte,third part corner holes are produced

and in second stage,the second part have center square

hole piercing.The above stage operations are done

simultaneously.

5.TRANSFER DIES:

Unlike the progressive die where the metal stock is fed

progressively from one station to another. But in transfer dies,

the already out blanks are fed mechanically from

station to station.

6.MULTIPLE DIES:

Multiple or gang dies produce two or more

workpieces at each stroke of the press. A gang or number

of simple dies and punches are ganged together to

produce two or more parts at each stroke of the press.

7.INVERTED DIES:

In generally, in punch holder plate punch is held,

which is fastened to the ram. Die is fitted with die holder,

which is held on press bed.

But in inverted dies, the punch and die are to be

interchanged. Punch is held in bed and the die is fastened

to the ram.

2 comments:

Great Tips! Its really working thanks for sharing this with us..

Ball End Screwdrivers

I got here much interesting stuff. The post is great! Thanks for sharing it! Deep Drawn Stainless Steel

Post a Comment